Many buyers ask me the same question the first time they see a rough terrain forklift:

“Is this model front-wheel steering1 or rear-wheel steering — and which one is better?”

It sounds like a small detail, but the steering system determines much more than you think —

it affects safety, handling, operator control, and real-world efficiency.

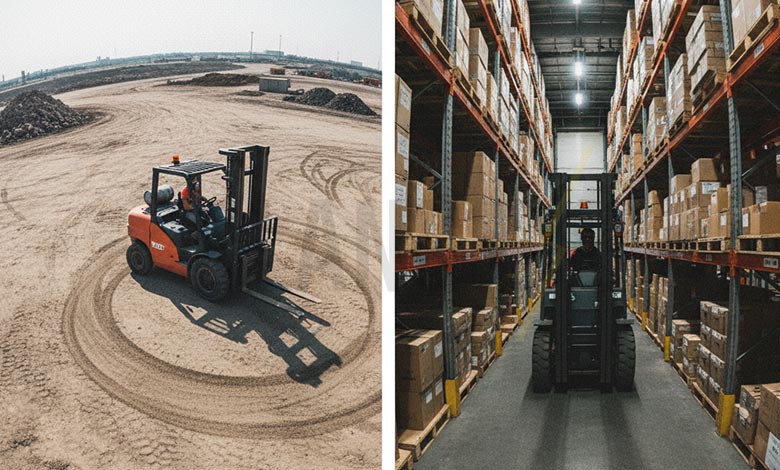

In rough terrain or tight job sites, even a small difference in turning behavior can decide whether the job goes smoothly or not.

The Core Difference

The biggest distinction between front-wheel and rear-wheel steering lies in where the steering pivot is and how the vehicle moves around it.

Rear-wheel steering offers a smaller theoretical turning radius2 and performs best in open outdoor sites.

Front-wheel steering provides more intuitive control3 and higher safety in tight or low-clearance areas.

In short:

Rear-wheel steering turns sharper. Front-wheel steering drives smarter.

Rear-Wheel Steering: Classic Design, Tighter Geometry

Rear-wheel steering is the most common layout for forklifts.

The front axle stays fixed, while the rear axle pivots to turn the machine around its center point.

This gives it a smaller turning radius on paper — and faster maneuvering in wide-open areas.

Advantages

- Smaller theoretical turning radius (about 20% shorter than front-steering models)

- Simpler design, easier to maintain

- Stable at higher travel speeds and in long runs

Limitations

- Tail swing is large — risky in narrow spaces

- The operator’s front view doesn’t match rear-wheel movement

- Works best on flat or semi-flat ground

| Item | Rear-Wheel Steering | Typical Performance |

|---|---|---|

| Steering Pivot | Near rear axle | Rotates around vehicle center |

| Turning Radius | Smaller (≈3.6 m) | Geometrically superior |

| Handling Difficulty | Higher | Tail swing risk |

| Ideal Site | Open, outdoor areas | Construction sites, yards |

Front-Wheel Steering: Intuitive Control for Tight Spaces

Front-wheel steering forklifts steer from the front axle — just like a car.

The operator can see exactly where the wheels are turning, and the rear end follows a predictable path.

That makes it safer and easier to control in confined or height-limited areas.

Advantages

- Intuitive, car-like steering feel

- No tail swing — safer near walls or obstacles

- More stable when loaded (weight over steering axle)

- Ideal for low or narrow environments

Limitations

- Slightly larger turning radius (around 4.5 m)

- More complex design, higher cost

| Item | Front-Wheel Steering | Typical Performance |

|---|---|---|

| Steering Pivot | Front axle | Direct steering response |

| Turning Radius | Larger (≈4.5 m) | Slightly wider |

| Operator View | Direct and intuitive | See wheel path clearly |

| Ideal Site | Tight, low-clearance areas | Basements, factories, loading zones |

Why a Smaller Turning Radius Doesn’t Always Mean “More Practical”

This is the most common misconception.

A smaller turning radius doesn’t automatically make a forklift more flexible in real operations.

Real-world maneuverability depends on:

- Tail swing risk (how much the rear sweeps during a turn)

- Operator visibility and steering feedback

- Control precision and margin for error

Rear-wheel steering may turn tighter, but its rear end swings widely —

which can easily hit walls or obstacles in tight areas.

Front-wheel steering moves in a way that’s more predictable and visible to the operator,

so it’s easier and safer to control, even if the radius is technically larger.

| Comparison | Rear-Wheel Steering | Front-Wheel Steering |

|---|---|---|

| Theoretical Radius | ✅ Smaller | Slightly larger |

| Tail Swing | ❌ Large | ✅ Minimal |

| Operator Visibility | ❌ Opposite direction | ✅ Forward-aligned |

| Control Margin | Medium | High |

| Real Maneuverability | Better in open areas | Better in confined spaces |

Which Steering Type Fits Which Job Site?

| Application Scenario | Recommended Steering Type | Reason |

|---|---|---|

| Construction site / Open yard | ✅ Rear-Wheel Steering | Wider space, faster turnaround |

| Basement / Tunnel / Factory aisle | ✅ Front-Wheel Steering | Narrow or low-clearance work |

| Port / Logistics zone | ✅ Front-Wheel Steering | Frequent short movements |

| Quarry / Rough ground | ✅ Rear-Wheel Steering | Strong traction, open path |

The Next Step: Articulated + 4WD Forklifts4

Modern rough terrain forklifts are evolving toward articulated front steering5,

allowing them to nearly pivot in place while maintaining 4WD power6.

This hybrid setup combines both advantages —

the compact geometry of rear steering and the intuitive control of front steering.

The future trend is clear: “Articulated + 4WD + Low Center of Gravity”

will define the next generation of rough terrain forklifts for confined or complex sites7.

Conclusion

In the world of rough terrain forklifts:

- Rear-wheel steering represents traditional agility and efficiency.

- Front-wheel steering represents modern safety8 and intuitive control3.

The question isn’t which one is “better” —

it’s where you’re working.

If your site is wide and open, rear-wheel steering will move faster and turn tighter.

But if you’re working in basements, tunnels, or tight indoor passages,

a front-wheel steering1 4WD rough terrain forklift will help you handle every turn with precision and peace of mind.

Explore this resource to understand how front-wheel steering enhances safety and control in tight spaces, crucial for effective forklift operation. ↩

Explore how turning radius affects operational efficiency in various environments. ↩

Learn why intuitive control is crucial for operator safety and efficiency. ↩

Explore this link to understand how 4WD forklifts enhance performance in rough terrains, ensuring safety and efficiency. ↩

Explore how articulated steering can improve efficiency in confined spaces. ↩

Learn about the benefits of 4WD in challenging environments. ↩

Discover which forklifts are best suited for challenging work environments. ↩

Stay updated on safety innovations that can protect operators and equipment. ↩