Introduction: Don't Just Look at Horsepower—Structure is the Soul of Off-Roading

Over the past few years, we’ve noticed a pattern: when customers choose a rough terrain forklift, they almost always look at "Tonnage, Horsepower, and Ground Clearance" first.

While parameters matter, the factor that truly determines how a forklift performs in mud, loose soil, steep slopes, and mines is a core design feature often overlooked: The Chassis Structure1.

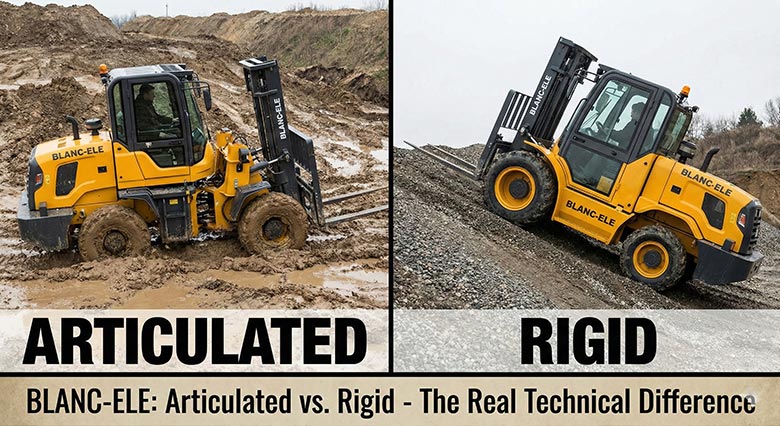

Articulated vs. Rigid: Which one should you choose?

If you have ever operated equipment in deep mud, gravel, large pits, or on long inclines, you would instantly feel the difference between the two. Today, BLANC-ELE2 breaks down the real technical differences to help you make the right choice.

1. What is a Rigid Frame?

The Rigid Frame is the most common structure on the market, often found in "light-duty" rough terrain forklifts.

Technical Characteristics:

- Chassis: The entire chassis is a single, solid block that cannot twist.

- Steering: Primarily relies on Rear-Wheel Steering3 (some high-end models use 4-Wheel Steer), while the front wheels handle the load and drive.

- Suspension: Relies on a limited Oscillating Rear Axle4 to adapt to uneven ground.

Limitations (in Rough Terrain Scenarios):

- Wheel Lift: Because the frame is stiff, if the ground unevenness exceeds the axle's oscillation range, you often end up with "three wheels on the ground, one in the air."

- Power Loss: Once a wheel is suspended in the air, without expensive differential locks, power flows to the spinning wheel, causing the vehicle to lose traction and get stuck.

- Large Turning Radius: Relying on rear steering makes it less agile in narrow mines, forests, or tight construction sites compared to articulated models.

The Verdict: Suitable for flat, hardened ground or light dirt roads, but limited capability in true off-road conditions.

2. What is an Articulated Frame? (Standard on All BLANC-ELE Models)

This is the standard structure for professional European mining equipment, forestry skidders, and high-end wheel loaders. BLANC-ELE2 has chosen this design across our entire range specifically to conquer true Rough Terrain.

Technical Characteristics:

- Chassis: Composed of a "Front Body + Rear Body" connected by a Floating Articulated Pivot.

- Steering: **Center Articulated Steering5, changing direction by folding the body in the middle.

- Ground Adaptation: The front and rear bodies can not only turn left and right but also Oscillate (twist) independently, actively conforming to rugged terrain.

Absolute Advantages:

- Full-Time 4-Wheel Ground Contact6: No matter how deep the pits are, the body twists like a snake, ensuring all four wheels stay firmly planted on the ground.

- Ultra-Small Turning Radius: Excellent maneuverability, allowing for U-turns in very tight spaces.

- Maximized Traction: Because the tires don't lose contact with the ground, every bit of horsepower is converted into effective traction, ensuring zero slip on slopes.

The Verdict: The Articulated design is born for bad roads. It is not a "beefed-up warehouse forklift"—it is a "specialized off-road vehicle equipped with forks."

3. [Technical Deep Dive] Beyond the Frame: The "Inner Strength" of the Chassis

Many customers ask: "Both are 4WD7, so why does the BLANC-ELE2 climb better?" The secret lies in the Axle Technology. This is the "invisible parameter" ordinary salespeople won't tell you about.

A. Ordinary Rigid Forklifts: Straight Axle

Many modified off-road forklifts simply reuse truck or tractor axles.

- Risk: The differential housing in the middle is bulky, resulting in low ground clearance and a high risk of "bottoming out."

- Power: Torque is transmitted directly. To get power, they rely on large displacement engines, which means higher fuel consumption and a risk of snapping axle shafts under stress.

B. BLANC-ELE Articulated Forklift8s: Hub Reduction Axle9

We utilize Hub Reduction Technology typically reserved for heavy construction machinery.

- The Principle: After power reaches the wheel center, it goes through a set of "planetary gears" for a secondary speed reduction and torque increase.

- Explosive Power: With the same engine horsepower, the torque output at the wheel is amplified by over 30%, providing immense power for starting and climbing.

- Better Clearance: The central axle housing is smaller, offering higher ground clearance to clear rocks and debris.

- Drivetrain Protection: Massive torque is generated at the wheel edge, reducing stress on the transmission shafts and extending component life.

4. Real-World Scenario Comparison

| Condition Type | Rigid Frame Performance | Articulated Frame Performance |

|---|---|---|

| Deep Pits / Uneven Ground | Stiff body leads to wheel lift, causing loss of traction. | 4-Wheel Ground Contact. Body twists with terrain; drives like it's on flat ground. |

| Mud / Rain | Rear steer creates drag; prone to pushing or slipping. | Excellent tracking. Combined with Hub Reduction, escape capability is superior. |

| Narrow Sites | Large turning radius; requires multiple reverse maneuvers. | Articulated Steering offers a tight radius and high agility. |

| Steep Slopes | Unstable grip; prone to tire spin. | Tires press firmly into the ground; torque output remains constant. |

| Durability | Bumps transfer directly to the frame. High vibration, faster wear. | Articulated structure naturally absorbs shock. Longer chassis lifespan. |

5. Why Does BLANC-ELE Insist on Articulated Frames?

Because we know our customers operate primarily in Southeast Asia, the Middle East, Africa, and South America. Your working conditions typically include:

- Construction Sites: Full of rebar, deep pits, and unpaved ramps.

- Farms & Forests: Soft mud, wet grass, and complex root systems.

- Mining Areas: Heavy loads and rugged terrain—the "graveyard" for ordinary forklifts.

In these scenarios, "being able to drive" isn't enough. You don't just need to carry the load in; you need to carry it out safely.

Since our customers demand true off-road capability, BLANC-ELE2 provides the only genuine off-road solution: Articulated Frame + Hub Reduction Axle9s.

Conclusion

If your work environment is mostly flat dirt roads, a Rigid forklift might be an economical choice. But if your site involves slopes, deep pits, soft mud, loose gravel, or narrow spaces, do not hesitate.

The Articulated Forklift8 is always the Safer, More Efficient, and More Reliable choice.

Want to know how BLANC-ELE Articulated Rough Terrain Forklifts can handle your specific site? 👉 [Contact our Technical Advisors Here]

Explore the importance of chassis structure in determining a forklift's capability in rough terrains. ↩

Explore this link to discover how BLANC-ELE forklifts excel in challenging environments, ensuring safety and efficiency. ↩

Learn how rear-wheel steering impacts maneuverability and handling in forklifts. ↩

Discover the role of oscillating rear axles in adapting to uneven ground for better stability. ↩

Find out how center articulated steering enhances maneuverability in tight spaces. ↩

Learn how maintaining 4-wheel ground contact improves traction and stability on rough terrain. ↩

Explore this resource to understand how 4WD forklifts enhance performance in challenging environments, ensuring safety and efficiency. ↩

Learn about articulated forklifts, their unique design, and why they excel in off-road conditions. ↩

Discover how hub reduction axles improve performance and efficiency in heavy machinery. ↩