Your forklift is stuck again, wheels spinning uselessly in the soft soil1. The harvest is waiting, the trucks are on their way, and your entire operation is halted by a patch of mud.

The right choice is a 4WD rough terrain forklift2. Its superior traction, high ground clearance3, and robust build are essential to navigate the soft soil, exposed roots, and uneven slopes4 common to plantations, ensuring you never get stuck.

When I talk to buyers from coconut and palm plantations, I hear the same frustration over and over. The problem isn’t lifting the massive weight of the harvest—it’s that ordinary forklifts simply cannot move on farm terrain. A standard 2WD machine, which works perfectly in a warehouse, becomes a liability the second it touches the soft, wet ground of a coconut field. It just spins in place. Palm farms are even tougher. The machine needs to handle exposed roots5 and cross ditches without getting its belly hung up. The reality of plantation work is that you need a machine that doesn't have to pick its path carefully. It just needs to work, everywhere.

Why do standard forklifts fail on soft plantation soil?

You bring in a standard forklift, and within minutes, it's dug itself into a rut. Now you're losing valuable time trying to tow it out instead of moving your harvest.

Standard forklifts fail because they use 2WD with tires designed for concrete. On soft soil1, their drive wheels spin without grip, and their low clearance6 causes the undercarriage to drag, quickly bogging them down.

I've seen it happen countless times. A farm manager tries to save costs by using a conventional forklift, and it ends up costing them more in lost time. The fundamental design is just wrong for the environment. Coconut fields, for example, are soft and uneven year-round, and the ground is often covered in a slippery layer of fallen husks and wet leaves.

Here’s a breakdown of the specific failures:

- Wrong Wheel Drive: A 2WD forklift7 sends power only to the front wheels. On soft ground, these wheels just dig themselves deeper holes the moment they lose traction. They have no "push" from the rear to get them out.

- Wrong Tires: Warehouse forklift tires are solid and smooth. They are designed for maximum stability on flat surfaces. On mud or wet leaves, they have zero grip, effectively turning into slicks.

- Wrong Clearance: Even a small amount of mud is enough to make the low-slung chassis of a standard forklift drag on the ground, creating resistance and eventually causing it to get completely stuck.

A standard forklift isn't just inefficient here; it's practically immobile.

How do palm farm obstacles stop a forklift cold?

You're driving through a palm grove and suddenly, a loud bang and a dead stop. Your forklift is high-centered on an exposed root, and now you have to check for serious damage.

Palm farm obstacles like exposed roots5, irrigation channels8, and uneven terrain stop a forklift by catching its low undercarriage. This "bellying out" lifts the wheels, causing a total loss of traction and potentially damaging vital components.

While coconut farms often defeat forklifts with soft ground, palm farms present a different, harder set of challenges. The ground is often firmer but littered with obstacles that are like traps for the wrong kind of machine. I always tell my clients that on a palm farm, ground clearance is even more critical than traction.

The main culprits are:

- Exposed Roots: Large, woody roots running along the surface are like solid steel bars to a forklift's undercarriage. A low-clearance machine will hit them and either stop dead or get lifted off the ground.

- Drainage and Irrigation Ditches: These small channels are essential for the farm but impossible for a standard forklift to cross. The wheels drop in, and the chassis gets stuck on the edges.

- Uneven Ground: Decades of growth and harvesting create a landscape of humps and dips. Without high ground clearance3 and an articulating suspension9, a forklift will constantly scrape its frame, risking damage to the transmission or hydraulic lines.

A machine has to be able to step over these obstacles, not get stopped by them.

How does 4WD provide constant uptime on a plantation?

You're tired of planning your routes around wet patches and small hills. This cautious driving wastes time and limits where your operators can work effectively, slowing down the entire harvest.

4WD ensures constant uptime10 by delivering power to all four wheels. Even if two wheels are on slippery mud or in the air, the other two can keep gripping and moving the machine forward.

This is the real reason I recommend a 4WD rough terrain forklift2—not because it’s “more powerful,” but because it simply keeps moving. On a plantation, uptime10 is everything. A machine that gets stuck is a machine that isn't earning its keep. The 4WD system provides the confidence to drive the most direct route from the harvest point to the truck.

| Here’s the practical difference it makes every day: | Scenario | 2WD Forklift's Reality | 4WD Forklift's Reality |

|---|---|---|---|

| A Patch of Mud | Stops, spins wheels, gets stuck. Requires a tow. | All four wheels engage, pushes through without stopping. | |

| Climbing a Wet Slope | Slides backward or spins out. Cannot make the climb. | Digs in with all four tires and climbs the slope steadily. | |

| Crossing a Ditch | Front wheels drop in, lose traction. Becomes stuck. | Front wheels may dip, but rear wheels push the machine across. |

With 4WD, the operator doesn't have to think about the ground conditions. They can just focus on the job. That is the definition of productivity on a farm.

What makes a forklift truly versatile for all-day farm work?

Your work isn't just one task. You need to collect bins deep in the field, navigate tight rows of trees, cross muddy tracks, and then precisely load them onto trucks at the roadside.

True versatility comes from a combination of agility, visibility, and power. The forklift must have a tight turning radius11 to work between trees, a clear view for safety, and the ability to handle any terrain it encounters.

A great plantation forklift isn't a one-trick pony. It has to be a master of several different environments, all within the same day. This is where the overall design of the machine becomes just as important as its 4WD system or ground clearance.

When I talk to plantation owners, we identify three key needs for all-day versatility:

- Maneuverability in Tight Spaces: Plantations are not open fields. A forklift needs excellent steering and a compact enough footprint to weave between rows of trees without damaging them. This is crucial for getting to the harvest point efficiently.

- All-Terrain Capability: The machine must seamlessly transition from the soft, uneven ground in the fields to muddy access roads and finally to the firmer ground where trucks are loaded. It cannot have a "weakness" on any of these surfaces.

- Operator-Focused Design: For long workdays, the operator needs good visibility in all directions to work safely and efficiently. Comfortable controls and an ergonomic cabin reduce fatigue, which directly translates to sustained productivity throughout the day.

A machine that excels in all three areas is a machine that will pay for itself.

How does the right forklift improve a plantation's bottom line?

You see the higher price tag on a rough terrain forklift and wonder if the investment is truly justified. You need to be sure it will deliver a real return, not just be an added expense.

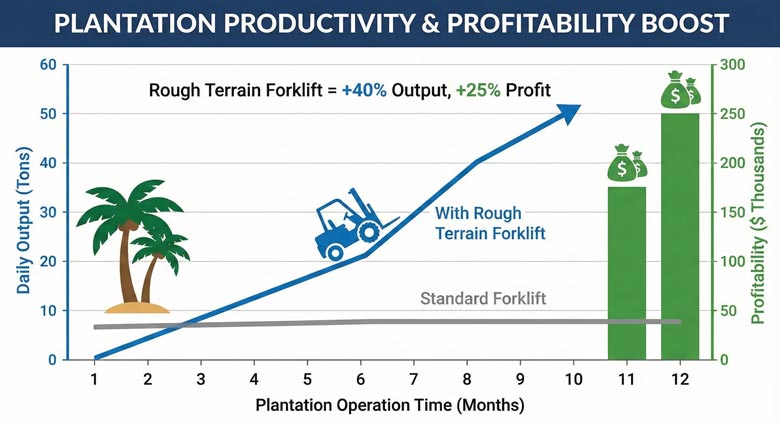

The right forklift improves the bottom line by maximizing productivity12 and minimizing downtime13. It moves more product per hour, reduces labor costs from stuck machines, and prevents costly delays during the critical harvest season.

This is the most important question of all. A forklift is a business tool, and its purpose is to make your operation more profitable. A cheap forklift that is constantly stuck is an expense, not an investment. A capable rough terrain forklift provides a return in several clear ways.

I always ask my clients to think about these points:

- Faster Cycle Times: How much faster can you get your harvest from the tree to the truck if your machine never has to slow down for bad ground or take a long detour? This speed directly increases your daily output.

- Reduced Labor Waste: Every time a machine gets stuck, you are paying your operator and often other staff to stand around or work on a recovery. A machine that doesn't get stuck eliminates this wasted expense completely.

- Harvest Security: During a harvest, time is critical. A delay of a day due to stuck equipment can mean losing part of a crop to weather or spoilage. The reliability of a rough terrain forklift is an insurance policy for your harvest.

In the end, the machine that doesn't stop working is the one that provides the best value.

Conclusion

On a plantation, a 4WD rough terrain forklift2 is not optional. It is the essential tool for ensuring your harvest moves efficiently from the field to the truck, regardless of the conditions.

Understand the difficulties forklifts face in soft soil and how to overcome them. ↩

Explore how a 4WD rough terrain forklift can enhance productivity and efficiency on plantations. ↩

Discover how high ground clearance can prevent damage and improve mobility in challenging environments. ↩

Get tips on safely operating forklifts on uneven terrain to avoid accidents. ↩

Find out how to navigate obstacles like exposed roots to maintain forklift efficiency. ↩

Understand the impact of low clearance on forklift mobility and efficiency in fields. ↩

Explore the drawbacks of 2WD forklifts in agricultural settings and consider better options. ↩

Learn how to navigate irrigation channels safely with forklifts to avoid getting stuck. ↩

Find out how articulating suspension enhances forklift performance on uneven surfaces. ↩

Explore the importance of uptime in maximizing productivity during harvest seasons. ↩

Learn how maneuverability can improve efficiency in tight spaces on farms. ↩

Explore strategies for improving productivity through the right forklift choice. ↩

Learn how to reduce downtime and keep operations running smoothly on farms. ↩