A Practical Guide to Emission Regulations, Power Matching, and Real-World Cost Efficiency

When customers inquire about a rough terrain forklift, the biggest confusion is often not the lifting capacity or attachments, but the engine configuration1 — and the price gap it creates.

Two forklifts with the same rated capacity can end up with very different prices simply because of the engine choice. From my experience at BLANC-ELE2 working with customers in different regions, this is rarely a matter of “cheap or expensive,” but a practical decision shaped by emission rules, operating conditions, and long-term usability3.

1. Engine selection is often decided by regulation, not preference

One of the first things I usually clarify is that engine selection is not always a free choice. In many markets, it is defined by local emission regulations4 and import requirements.

Typical regulations and engine choices by region

| Market Region | Typical Regulation | Common Engine Options |

|---|---|---|

| Europe / Israel | EU Stage V / Euro V | Cummins QSF, Deutz TCD, Yanmar 4TNV |

| North America | EPA Tier 4 Final | Cummins, Kohler, Kubota |

| Southeast Asia / Middle East / Africa | Stage II / III (less regulated) | Yunnei, Xinchai, Yuchai, Weifang |

In markets such as Israel or the EU, a Euro V5–compliant engine is mandatory for legal import and registration. In these cases, choosing a higher-emission-standard engine is not an upgrade — it is simply the only compliant option.

2. Why the engine has such a strong impact on forklift price

A question I hear very often is:

“Why is there such a big price difference between two 3.5-ton rough terrain forklifts6?”

From a manufacturing point of view, the engine is usually the largest single contributor to that difference.

Well-known global engines have transparent pricing, and they are genuinely expensive. In many configurations, the cost of a Cummins or Deutz engine alone can exceed the combined cost of several other optional items, such as:

- Side shifters7

- Bucket8ts](https://www.blanc-ele.com/rough-terrain-forklift-attachments-configurations-complete-buyers-guide/)%%%FOOTNOTE_REF_9%%% or bale clamp10ps](https://www.blanc-ele.com/forklift-drive-types-explained-fwd-rwd-4wd/)%%%FOOTNOTE_REF_11%%%

- Heating and air conditioning

- Solid tires or reverse cameras

This does not mean the engine is overpriced. It reflects the cost of emission systems, certification, brand standards, and long-term global support. But it is important for buyers to understand where the money is actually going.

3. Not every market needs a high-emission-standard engine

In many Southeast Asian, Middle Eastern, and African markets, the actual working environment does not require Euro V5 or Tier 4 Final engines.

In these regions, mature and proven engines such as Yunnei, Yuchai, Weifang, or Xinchai are widely used because they are:

- Technically stable

- Easy to maintain locally

- Well matched to real operating conditions

I often tell customers something very simple:

The purpose of buying a rough terrain forklift is to make your work easier and more efficient.

The right engine is the one that fits your conditions — not necessarily the most expensive one.

4. Power matching matters more than many buyers expect

Another common situation is choosing a lower-power engine to reduce initial cost.

This is where experience matters. An underpowered engine on a higher-capacity rough terrain forklift does not just affect speed — it can limit the machine’s real lifting ability and reduce safety margins.

In real applications, this can mean:

- Slower and less stable hydraulic performance12 under load

- Difficulty working on slopes or soft ground

- Higher stress on the drivetrain and cooling system

From a manufacturing perspective, engine power is not about whether the forklift can move, but whether it can operate safely and consistently under real working conditions.

5. Real-world examples from customer projects

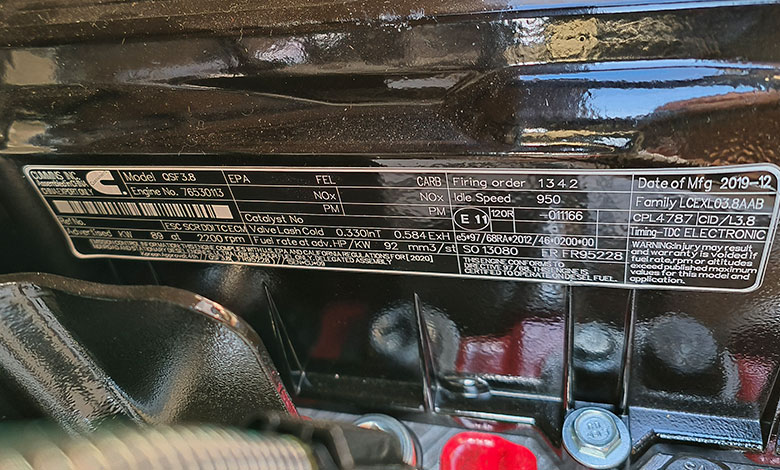

Case 1: Compliance-driven choice in Israel

An Israeli customer initially focused on reducing engine cost. Once local Euro V5 requirements were confirmed, the choice became clear.

We configured the forklift with a Stage V–compliant Cummins engine, ensuring smooth import, registration, and long-term legal operation. While the initial cost was higher, it avoided compliance risks that could have caused serious delays or losses later.

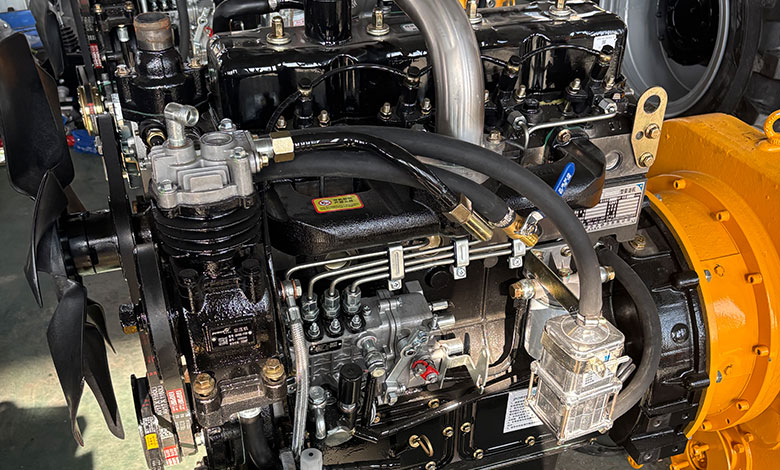

Case 2: A practical configuration for a Malaysia customer

A customer in Malaysia originally considered a higher-cost Western engine, mainly out of concern for long-term reliability.

After discussing local regulations, service availability, and actual site conditions, we recommended a mature and well-proven Yunnei engine13 instead.

By saving on the engine, the customer invested more in functional attachments14 such as a side shifter, bucket, and bale clamp10. This allowed the forklift to handle a wider range of tasks on site and made the overall machine more useful in daily operations.

The customer later told me that this configuration made more sense in practice than the higher engine specification he first considered. He has been satisfied with the machine’s performance and continues to introduce new customers to us — feedback like this is always more convincing than specifications on paper.

6. Why engine specifications alone can be misleading

On a rough terrain forklift, the engine is never an isolated component. It must work together with:

- The transmission

- The hydraulic system

- The cooling system

The same engine can perform very differently depending on how the entire machine is designed and matched. This is why comparing engine.

Conclusion

There is no single “best engine” for a rough terrain forklift. The right choice depends on emission compliance, correct power matching15, and how the machine will actually be used.

If a forklift can operate reliably in your environment and support your daily work without unnecessary complications, then its engine configuration1 is the right one.

At BLANC-ELE2, we focus on helping customers make that practical decision — not just on selling higher specifications.

Choosing the right engine configuration can significantly impact performance and cost-effectiveness. ↩

Explore BLANC-ELE's expertise in forklift solutions to understand how they help customers make informed engine choices. ↩

Explore strategies for maximizing the longevity and usability of your forklift investment. ↩

Understanding emission regulations is crucial for compliance and operational efficiency in different markets. ↩

Learn about Euro V compliance and its importance for legal import and operation in Europe. ↩

Explore this link to discover top models, features, and expert insights on 3.5-ton rough terrain forklifts for your needs. ↩

Explore this resource to understand how side shifters enhance forklift versatility and efficiency in various applications. ↩

Explore this resource to discover the most effective bucket options that enhance the versatility and efficiency of your rough terrain forklift. ↩

Explore this resource to discover the most effective bucket options that enhance the versatility and efficiency of your rough terrain forklift. ↩

Explore this resource to understand how a bale clamp enhances forklift functionality, improving efficiency in handling materials. ↩

Explore this resource to understand how bale clamps enhance efficiency and versatility in handling materials. ↩

Understanding the link between engine choice and hydraulic performance can enhance operational efficiency. ↩

Find out why Yunnei engines are favored in certain markets for their reliability and cost-effectiveness. ↩

Explore how functional attachments can improve the versatility and efficiency of your forklift. ↩

Discover how power matching affects performance and safety in forklift operations. ↩