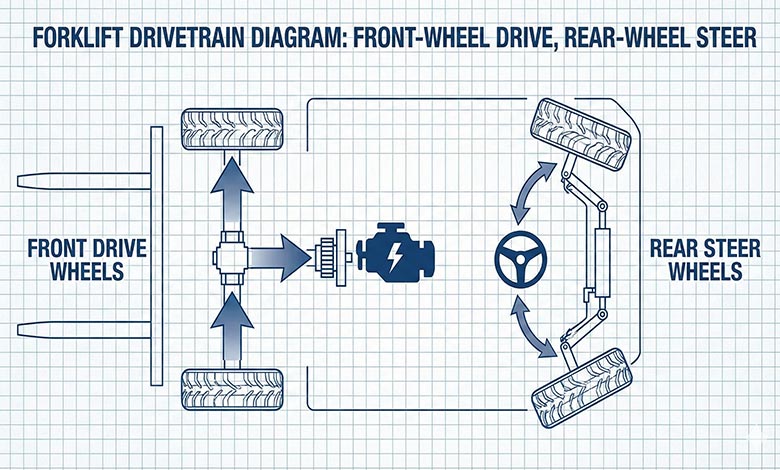

Quick Answer: Most standard counterbalance forklifts are Front Wheel Drive (FWD)1 with Rear Wheel Steering2. This configuration allows the front wheels to provide maximum traction under heavy loads, while the rear wheels pivot to offer an extremely tight turning radius in narrow aisles.

1. Why Most Counterbalance Forklifts Are Front Wheel Drive

In a typical industrial forklift, the front wheels drive the truck, while the rear wheels steer. This is the standard for 90% of the forklifts you see in warehouses.

The reason is practical physics: Traction follows weight.

When a forklift picks up a heavy pallet:

- The center of gravity shifts forward.

- Ideally, 80-90% of the total weight (truck + load) rests on the front axle.

- By driving the front wheels, the forklift uses this massive weight to press the tires into the ground, gaining excellent grip for acceleration and braking.

If a loaded forklift were Rear Wheel Drive, the heavy load would lift the weight off the rear drive wheels (the "teeter-totter" effect), causing them to spin helplessly on the floor.

2. Why Forklifts Use Rear Wheel Steering

If the front wheels do the driving, why do the rear wheels do the steering?

Maneuverability.

Rear-wheel steering allows the forklift to pivot around its front drive wheels. This creates a much tighter turning circle than a car (which steers from the front). This design is what allows forklifts to stack pallets in aisles that are barely wider than the truck itself.

Note for Operators: This is why the "tail swing" exists. When you turn left, the rear of the forklift swings wide to the right.

3. Are There Any Rear Wheel Drive Forklifts?

Yes, but they are the exception, not the rule. You might see Rear Wheel Drive (RWD)3 in:

- 3-Wheel Electric Forklifts: Some compact electric models use a single rear drive wheel (or dual rear drive) to achieve a 90-degree turn for extreme agility.

- Light-Duty Stackers: Where load capacity is low enough that traction isn't the primary concern.

However, for the standard "Sit-Down Counterbalance4" forklift used in factories, FWD is the industry standard.

4. When "FWD vs. RWD" Becomes "2WD vs. 4WD"

The Front Wheel Drive layout works perfectly on smooth concrete. But once the forklift leaves the warehouse, the rules change.

On construction sites, farms, or unpaved yards:

- FWD Limitation: If the front drive wheels hit a patch of mud, they can spin, and the unpowered rear wheels act as a dead weight anchor.

- The Solution: This is why Rough Terrain Forklifts5 (like the BLANC-ELE) use 4WD (Four Wheel Drive)6.

A 4WD forklift powers all four wheels. This ensures that even if the front tires slip in mud, the rear tires push the machine forward, combining the agility of a forklift with the traction of a tractor.

Conclusion

To summarize:

- Standard Forklifts: Are Front Wheel Drive (for traction) and Rear Wheel Steer (for turning).

- Rear Wheel Drive: Is mostly found on small, compact electric units.

- Outdoor Forklifts: Should be 4WD to handle rough ground.

Don't confuse "steering" with "driving." Understanding this difference ensures you pick the right machine for your terrain.

Need a forklift that handles more than just flat concrete? [Explore BLANC-ELE7's 4WD Rough Terrain Forklifts5] and get the traction you need for tough jobs.

Discover the benefits of FWD forklifts, including improved traction and stability under heavy loads. ↩

Learn how Rear Wheel Steering enhances maneuverability, allowing forklifts to navigate tight spaces effectively. ↩

Explore the specific scenarios where RWD forklifts are beneficial, especially in compact and light-duty applications. ↩

Understand the advantages of Sit-Down Counterbalance forklifts for industrial applications. ↩

Get insights into essential features of Rough Terrain Forklifts to ensure they meet your outdoor needs. ↩

Find out how 4WD forklifts provide superior traction and performance on uneven surfaces. ↩

Discover the unique advantages of BLANC-ELE forklifts, especially their 4WD models designed for rough terrain, ensuring optimal performance. ↩