After years in the rough terrain forklift1 industry, I’ve become convinced of one thing: A truly good forklift isn’t judged only by horsepower or lifting capacity—it's judged by how easy it is to maintain.

Many customers think I'm trying to upsell them when I say this. But after working with thousands of machines across construction sites, farms, plantations, and mining areas, I know the truth:

A rough terrain forklift1 doesn’t become expensive because it breaks. It becomes expensive because it stays broken.

This is exactly why at BLANC-ELE, we treat “maintenance-friendly design2” as a core engineering priority—not an afterthought.

1. Why Easy Maintenance Matters More Than Most Buyers Realize

Off-road environments are harsh and unpredictable: mud, deep ruts, rocks, water, dust, and constant vibration.

This creates higher-than-average needs for:

- Frequent lubrication to prevent grinding.

- Faster wear on pins and bushings due to grit.

- Regular inspection of moving parts.

If forklift maintenance tasks3 require lifting seats, removing heavy panels, or crawling underneath the chassis, here's what happens:

Maintenance gets delayed → friction increases → wear accelerates → failures come sooner → downtime becomes routine.

As I often tell customers:

“A forklift isn’t costly because it breaks—it’s costly because it stays broken.”

That belief shapes the design philosophy of every BLANC-ELE RT Series machine.

2. External Oil Filling Ports: Saving Time and Preventing Contamination

Many buyers are surprised when they see BLANC-ELE forklifts4 feature external hydraulic and transmission oil filling ports5:

“No seat removal? No screws? No crawling under the machine?”

Exactly. That’s intentional.

Why this matters:

- Contamination Control: Opening internal compartments in a dusty field invites dirt into your hydraulic system. External ports keep the system sealed and clean.

- Speed: Operators spend less time prepping and more time working.

- Safety: No awkward positioning or heavy lifting to access fluids.

This design is used across the BLANC-ELE product line for one reason:

“The easier the maintenance, the longer the machine lasts.”

Simple access encourages consistent checks—and consistent checks keep rough terrain forklift1s alive.

3. Centralized Lubrication: Greasing Should Take Minutes, Not Half an Hour

Most brands hide grease points deep under the machine axle or behind the mast. At BLANC-ELE, we do the opposite:

All major lubrication points are routed to accessible ports on the machine exterior.

Practical advantages:

- No crawling under the forklift in the mud.

- No guessing where each grease point is hidden.

- No removing guards just to do a daily check.

- Daily lubrication takes just minutes, ensuring it actually gets done.

In rough terrain, inadequate lubrication is the #1 cause of premature pin and bushing wear.

That’s why I always tell buyers:

“Most cheap forklifts don’t break from heavy lifting—they break from poor lubrication access.”

Centralized lubrication is one of BLANC-ELE’s signature durability features that dramatically extends service life.

4. Easy-to-Service Electrical System: Fast Troubleshooting

Forklift electrical issues are common in outdoor environments due to moisture, dust, and vibration. For this reason, all BLANC-ELE machines place the fuse box in a high-visibility, tool-free, easy-to-open position.

We also include:

- Spare fuses built-in.

- Clear circuit labeling (no guessing games).

- Clean wiring layout for quick tracing.

Why is this so important? Because a minor blown fuse shouldn’t halt an entire job site for half a day.

As I like to say:

“Outdoor work doesn’t fear breakdowns—it fears not knowing where the problem is.”

BLANC-ELE forklifts4 are designed so operators can diagnose issues quickly—often getting back to work within minutes.

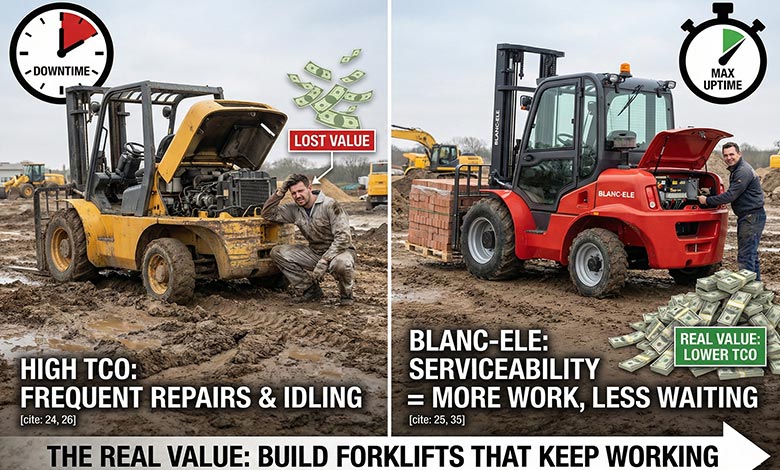

5. The Real Value: Lower Total Cost of Ownership (TCO)

You don’t buy a rough terrain forklift1 to admire it—you buy it to work.

And whenever it stops, you lose:

- Labor hours

- Fuel (idling while troubleshooting)

- Contract progress

- Operational efficiency

This is why BLANC-ELE focuses heavily on serviceability6.

Easy maintenance directly reduces:

- Service labor costs.

- Troubleshooting time.

- Wear caused by overdue lubrication.

And it increases:

- Machine lifespan.

- Resale value.

- Real usable working hours.

In rough terrain environments:

“The most expensive cost isn’t the repair part—it’s the downtime.”

At BLANC-ELE, our design philosophy is simple: Build forklifts that keep working, not forklifts that keep waiting.

Conclusion

A rough terrain forklift1’s true value is not defined by brochure numbers. It is defined by how reliably it stays on the job—and how quickly it gets back to work when service is needed.

BLANC-ELE’s maintenance-focused engineering ensures:

- External oil filling ports for contamination-free servicing.

- Centralized lubrication that prevents wear.

- Accessible electrical systems for rapid troubleshooting.

Stop paying for downtime.

[Check out the BLANC-ELE RT Series Features] or [Contact our Support Team] to learn how we keep your operation moving.

Explore the advantages of rough terrain forklifts to understand their unique capabilities and applications. ↩

Learn how maintenance-friendly design can enhance equipment longevity and reduce costs. ↩

Discover essential maintenance tasks to keep your forklift running efficiently and safely. ↩

Explore this link to understand how BLANC-ELE forklifts enhance efficiency and reduce downtime with their innovative design. ↩

Find out how these ports improve maintenance efficiency and prevent contamination. ↩

Discover the significance of serviceability in reducing downtime and maintenance costs. ↩