After so many years in this industry, I’ve noticed one recurring reaction from new buyers. When I tell them “machine weight reflects build quality1,” they often look skeptical, thinking I’m just trying to upsell them on shipping costs or material.

But once I take them to the yard and show them the physical differences in steel thickness, weld penetration, and axle density, they instantly understand: Two forklifts may look identical in a brochure — but they are not built the same.

To make the differences clear, I’ve broken them down into the 8 factors that matter most in real-world use.

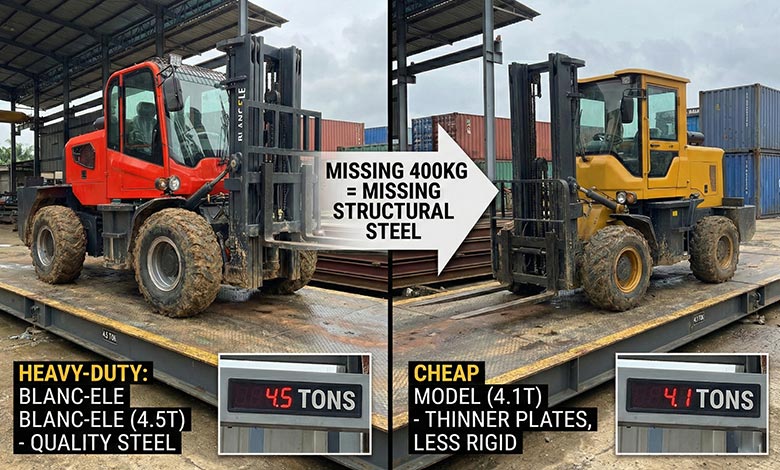

1. Machine Weight: The Most Straightforward Indicator of Quality

In the 3.5-ton segment, a true heavy-duty rough terrain forklift2 should weigh around 4.5 tons. Many cheap models3 on the market weigh only 4.1–4.2 tons.

Customers often ask me:

"Why is there such a big weight difference if the lifting capacity is the same?"

And I always give them the same answer:

“The BLANC-ELE4 forklift isn’t expensive — the one you compared it to is simply too cheap.”

Weight doesn’t lie. That missing 300-400kg isn't just "fat"; it's missing structural steel. It represents thinner plates, hollower castings, and a frame that is less rigid.

Heavy-Duty vs. Cheap Forklift: The Real Specs

| Component / Feature | Heavy-Duty Forklift (BLANC-ELE) | Cheap Rough Terrain Forklift |

|---|---|---|

| Machine Weight | ~4.5 tons (Solid stability) | ~4.1–4.2 tons (Tipping risk) |

| Steel Thickness | 16mm main structural plates | 14.8mm or thinner |

| Tilt Cylinders | Mounted to Main Chassis | Welded to Fenders (Deforms easily) |

| Fenders | Heavy-duty steel, independent | Thin metal, load-bearing (Bad design) |

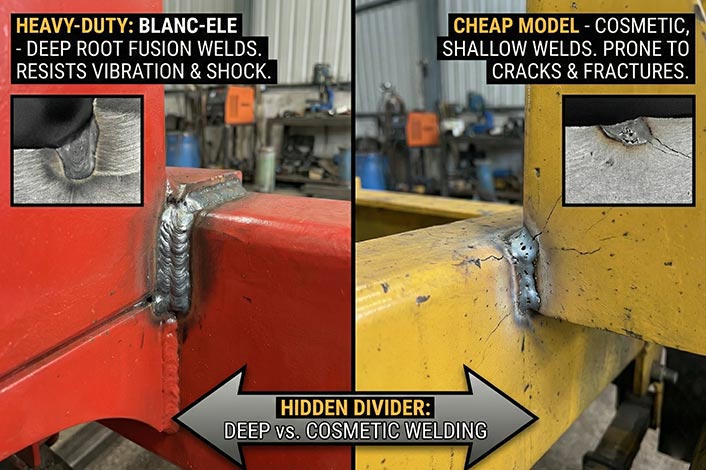

| Welding Quality | Multi-pass, deep penetration | Shallow, cosmetic surface welds |

| Axles | Reinforced cast steel housings | Thin housings, prone to leaks/cracks |

| Service Life | 8–12 years | 2–4 years before major overhaul |

This is the truth: One machine is engineered for a decade of work. The other is built to survive the warranty period.

2. Steel Thickness: “Does 1mm Really Matter?”

This is the question I hear most often:

"Does 1mm of steel really make such a big difference?"

Yes — more than you think.

Steel plates are not paper. The difference between 16mm vs. 14.8mm across an entire chassis translates to massive differences in torsional rigidity.

At BLANC-ELE4, we stick to 16mm. Why? Because thin plates lead to:

- Frame twisting under uneven loads.

- Fatigue cracks near weld points.

- Mast distortion over time.

Thicker plates are the foundation of a forklift that lasts 10 years instead of 3.

3. Tilt Cylinder Mounting: The Easiest Way to Spot Corner-Cutting

If you want to know if a manufacturer is cutting corners, look at where the Tilt Cylinders (the hydraulic pistons that tilt the mast) are attached.

- The Cheap Way: The cylinders are welded directly onto the fenders. Fenders are usually thin metal. Over time, the force of the mast pulls on the fenders, causing them to warp. Once the fender bends, your headlights misalign, your cabin floor shifts, and your mast loses precision.

- The Heavy-Duty Way (BLANC-ELE4): Our fenders are non-load-bearing. The tilt cylinders5 are mounted directly to the main chassis frame. You could remove the fenders entirely, and the machine would still work perfectly.

This is a classic situation where the factory saves money, but the customer pays the price with a warped machine.

4. Welding Quality: The Hidden Divider

Rough terrain forklifts6 endure continuous vibration and sudden shocks from potholes and roots. This vibration is the enemy of bad welds.

Cheap machines often rely on cosmetic welds—they look smooth on the surface but lack deep penetration (root fusion). Under constant vibration, these shallow welds develop hairline cracks, leading to:

- Cracked mast bases.

- Frame fractures.

- Detached mounting brackets.

Good welding isn't just about sticking two pieces of metal together; it's about fusing them into one. You won't see the difference on day one, but you will definitely feel it on day 400.

5. Axles & Steering: The Parts That Take the Abuse

The axle is the single most expensive component to replace if it fails.

Cheap axles7 often use thin cast iron housings to save weight. They are prone to:

- Developing "play" or looseness quickly.

- Leaking oil from stress fractures.

- Snapping under heavy load on a slope.

We use reinforced, heavy-duty axle assemblies. Extra steel in the housing acts as a heat sink and a shield. It is not a "premium feature"—it is a survival requirement for rough terrain work.

6. Mast Structure & Slider Durability

The mast looks simple, but it acts as a giant lever arm.

- Cheap Masts: Use narrow profiles and soft steel sliders. After a few months of dust and mud, the sliders wear out, and the mast starts to "wobble" with a load in the air.

- Heavy-Duty Masts: We use a wide-view mast with reinforced sliders and rollers. This minimizes sway and ensures that when you place a pallet at 4 meters high, it goes exactly where you want it.

The question is not “Can it lift?” The real question is “Can it keep lifting precisely for years?”

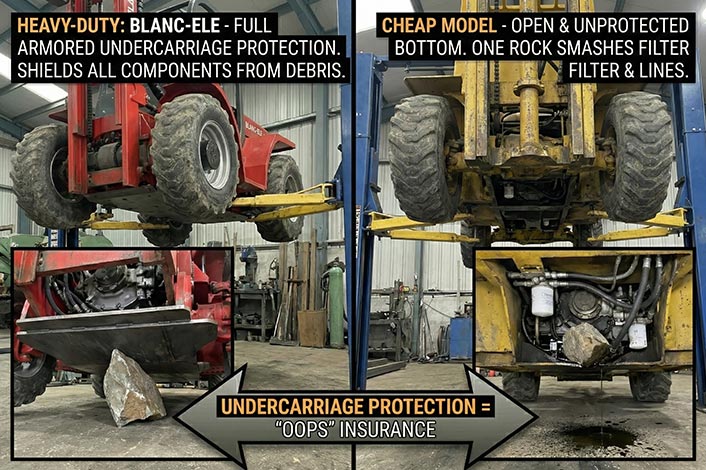

7. Undercarriage Protection: The "Oops" Insurance

In a plantation or construction site, you will run over rocks, stumps, and debris.

Cheap forklifts often leave the bottom open to save on steel. One sharp rock can smash a transmission filter or tear a hydraulic line, stopping your operation for days.

BLANC-ELE4 machines come with full armored undercarriage protection8. We treat the bottom of the machine as seriously as the top, ensuring that field debris stays outside where it belongs.

8. Total Cost of Ownership (TCO): Cheap is Expensive

Many buyers choose a cheap forklift thinking they’re being smart with their budget. A year later, they usually call me saying:

"Repairs are too frequent. Downtime is killing my harvest. I should have bought the heavier one."

Cheap forklifts carry hidden taxes:

- Constant seal replacements.

- Downtime during critical work windows.

- Zero resale value (nobody wants a warped frame).

Durability is the real economy. A machine that runs without issues for 5 years is cheaper than a machine that costs 20% less but stops working every month.

Conclusion

The difference between a heavy-duty rough terrain forklift%%%FOOTNOTE_REF2%%% and a cheap one isn't in the paint job. It’s in the **weight, the 16mm steel, the chassis-mounted cylinders, and the reinforced [axles](https://en.wikipedia.org/wiki/Crane(machine))7.**

As I always tell my customers:

“The forklift isn’t expensive — the one you compared it to is simply too cheap.”

Invest in a machine that protects your profit margins, not one that eats into them.

Ready to see the difference for yourself? Contact the BLANC-ELE4 team today for a detailed spec comparison.

Understanding how machine weight correlates with build quality can help you make informed purchasing decisions. ↩

Explore the advantages of heavy-duty forklifts to ensure you choose the right equipment for your needs. ↩

Learn about the potential pitfalls of opting for cheaper forklift models to avoid costly mistakes. ↩

Discover the unique features of BLANC-ELE forklifts that enhance performance and reliability. ↩

Understanding tilt cylinder mounting can help you identify quality differences in forklifts. ↩

Explore this resource to understand essential features that ensure durability and performance in rough terrain forklifts. ↩

Learn about the importance of axles in maintaining the reliability and safety of forklifts. ↩

Explore how undercarriage protection can prevent costly damage and downtime. ↩