Your standard forklift starts up a slope, then the wheels begin to spin uselessly. The whole machine groans to a halt, stranded halfway up, with the entire job site watching.

The best forklift for hilly terrain is a 4WD rough terrain model. Its superior traction, enhanced stability, and controlled engine braking are essential for safely and efficiently navigating slopes where standard forklifts consistently fail.

I've had this conversation so many times with customers. They have a perfectly good 2WD forklift that works great in the yard, but the moment they take it onto a site with any real hills, it becomes a liability. The story is always the same: it struggles, the steering feels vague, and it loses all its real-world performance. The biggest mistake I see is people thinking "a forklift is a forklift." On hilly terrain, that is a dangerously incorrect assumption. You're past the point where a regular forklift makes sense, and you're entering territory where you need equipment that's actually designed for the challenge.

Why do standard forklifts lose so much power on hills?

You’ve seen it happen. Your forklift, rated to lift three tons, can barely get itself up an incline. You're left wondering where all that power and performance suddenly went.

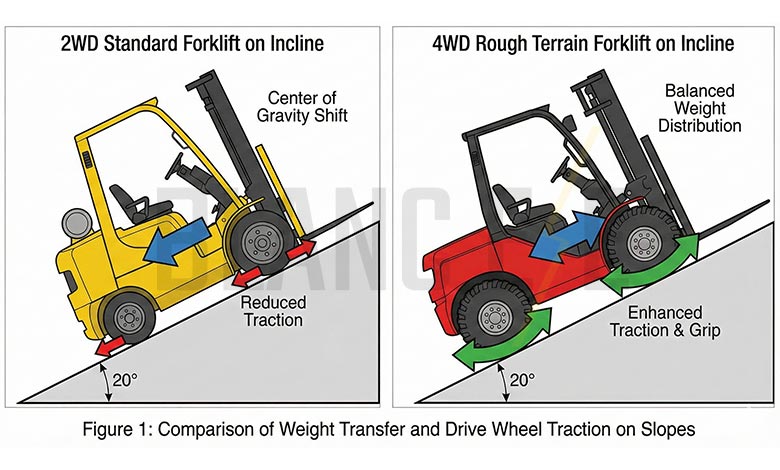

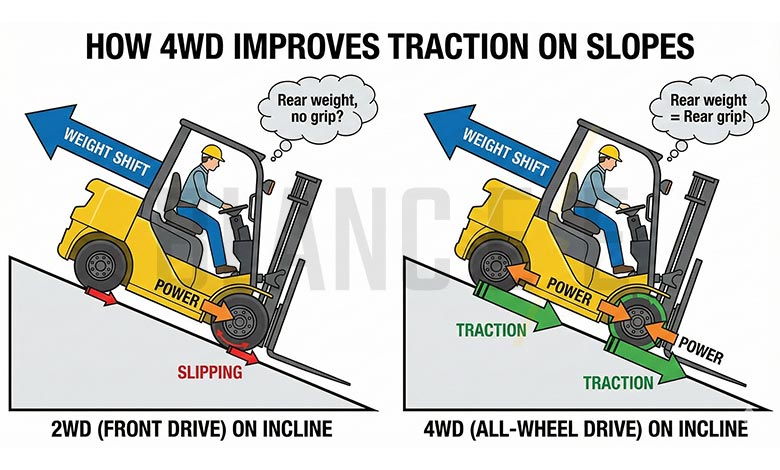

On a hill, a standard forklift’s power becomes useless because its front drive wheels lose traction. As the machine tilts upward, weight shifts to the rear, unloading the very wheels that need grip to climb.

I tell my clients to think of it this way: the machine is actively working to defeat itself. A standard 2WD forklift is a front-wheel-drive machine. All the power to move forward is sent to the front axle. But as soon as you drive up an incline, gravity pulls the machine’s center of mass backward, lifting the weight off those critical front wheels. The tires might have plenty of tread, but if there isn't enough weight pushing them onto the ground, they'll just spin on loose dirt or gravel. Stopping halfway up a hill is even worse. Trying to get moving again from a dead stop on a slope with a 2WD machine is almost guaranteed to fail. You don't have the traction to overcome the inertia and gravity. It’s not a defect; it’s just the wrong design for the job.

What makes going downhill so unpredictable?

You assume that since gravity is on your side, coming down is the easy part. But you’ve watched operators fight to control their speed, with the machine feeling like it wants to run away.

Going downhill is unpredictable because the load’s momentum can easily overwhelm a standard forklift’s braking system. The brakes overheat, and the load effectively pushes the machine, causing skids and loss of control.

From my experience, this is where the most serious accidents happen. A site manager in a hilly region once told me his biggest fear was not getting stuck going up, but skidding on the way down. He’s right to be worried. A standard forklift's brakes are designed for stopping on flat, hard surfaces. They are not designed to manage the massive, continuous force generated by a multi-ton machine on an incline.

The brakes heat up very quickly under this strain, leading to "brake fade"—where they become less and less effective. The operator has to push harder and harder on the pedal with diminishing results. On loose soil or gravel, even a small tap on the now-overheating brakes can cause the wheels to lock and the entire forklift to slide sideways. At that point, the operator is just a passenger.

How does a 4WD system prevent wheel spin?

You understand you need more traction, but you're wondering how 4WD actually solves the problem. Does it just add power, or does it work in a fundamentally different way?

A 4WD system solves the problem by ensuring continuous traction. By delivering power to all four wheels, it uses the weight that shifts to the rear axle to provide the grip needed to climb steadily.

This is the game-changer for hilly terrain. A 4WD rough terrain forklift turns the physics of a slope from a disadvantage into an advantage. As the machine climbs and weight shifts to the back, that weight is now pressing down on powered rear wheels. Those wheels dig in and provide the push needed to keep moving forward, while the front wheels continue to pull.

Here is a clear breakdown of the difference this makes:

| Situation | Standard 2WD Forklift | 4WD Rough Terrain Forklift |

|---|---|---|

| Climbing Loose Soil | Front wheels spin, digging ruts. The machine stops, unable to proceed. | Rear wheels dig in and push, front wheels pull. The machine maintains steady forward progress. |

| Uneven Ground | If one front wheel lifts slightly, all forward drive can be lost. | Power is distributed. Even if one wheel has less grip, the other three keep the machine moving. |

| Stopping on a Hill | Restarting is nearly impossible due to immediate wheel spin. | The machine can start moving again from a complete stop, with all four wheels gripping the surface. |

With 4WD, the operator has constant, reliable control. The machine feels planted and secure.

Is stability on hills only about traction?

You're sold on 4WD for traction, but you know hills are also uneven and full of dips and bumps. What stops the forklift from tipping over when the ground isn't just sloped, but also rough?

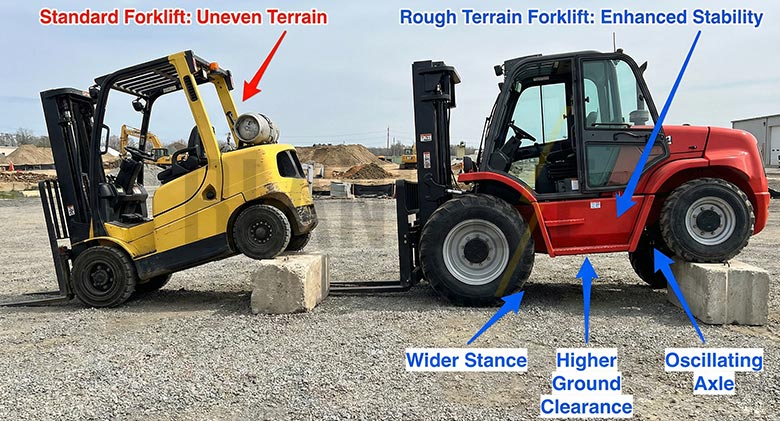

No, stability is about the entire machine's design. Rough terrain forklifts have a wider stance, higher ground clearance, and often an oscillating axle that allows wheels to stay on the ground on uneven surfaces.

This is another reason why the "a forklift is a forklift" idea is so dangerous. A standard forklift is built like a tricycle, with its main stability coming from the front axle. On uneven ground, this design is very susceptible to tipping. A purpose-built rough terrain forklift, however, is engineered for this exact environment.

The key components that create this stability are:

- Wider Wheelbase: A wider, more aggressive stance makes the machine inherently more resistant to tipping sideways.

- Higher Ground Clearance: This allows the forklift to clear rocks, ruts, and debris without the undercarriage getting hung up, which could easily destabilize a standard machine.

- Oscillating Axles: Often found on the rear steering axle, this feature allows the axle to pivot. If one wheel goes into a dip, the axle tilts so that both wheels can remain in firm contact with the ground. This keeps the machine's main frame and the load far more level and stable, dramatically reducing the risk of a rollover. These features work together with the 4WD system to create a machine that remains secure and predictable on unpredictable terrain.

How does the right forklift make descending safe?

You understand how 4WD helps you get up the hill. But what is the specific feature that prevents the machine from running away on the controlled, but scary, trip back down?

The right forklift uses its transmission for engine braking. By selecting a low gear, the engine itself controls the descent speed, keeping it slow and steady without ever needing to rely on the service brakes.

This is the safety feature that truly separates a professional rough terrain machine from a standard one. It completely changes the dynamic of going downhill. Instead of a battle against momentum, it becomes a smooth, controlled procedure. The operator simply puts the machine in low gear at the top of the hill. The drivetrain is engineered to hold the forklift back, preventing it from accelerating.

The practical effect is a slow, walking-pace descent. The operator doesn't have to touch the brake pedal at all until they reach the bottom and want to come to a complete stop. This eliminates the risk of brake overheat and failure. It prevents the terrifying skids that happen when braking on loose surfaces. It keeps the operator fully in control of the machine at all times. This isn't just an upgrade; it is the safe and professional way to handle hills.

Conclusion

On hilly terrain, choosing a 4WD rough terrain forklift is not an upgrade—it's a fundamental requirement. It ensures the safety of your operator and the productivity of your entire project.