Your operator is halfway up a ramp when the drive wheels start to spin. The forklift lurches, the load shifts, and for a terrifying second, you're not sure if it's going to make it or slide back down.

To work safely on slopes, always drive straight up or down, never across. Keep the load pointed uphill at all times, use a 4WD machine1 for reliable traction, and descend slowly in a low gear, letting the engine help with braking.

I've been talking to customers about worksite safety for over a decade, and let me tell you, slopes are a major point of anxiety. Most of the near-misses I hear about aren't due to reckless operators. They happen because someone is trying to do a job with the wrong machine. A standard 2WD forklift2 just isn't built for inclines. I've heard stories of steering getting dangerously light, machines losing grip, and even rollovers. That's why my advice always starts with one question: "Do you have the right forklift for the hill in the first place?"

What’s the biggest risk when going uphill?

You see an operator approaching a ramp. Your biggest fear is that the forklift will run out of power and roll backward, creating a dangerous and uncontrolled situation.

The biggest risk is losing traction3. As the incline increases, weight shifts to the rear, unloading the front drive wheels of a standard 2WD forklift2. This causes them to spin, resulting in a complete loss of control.

An operator for a landscaping company once described this feeling to me perfectly. He said, "You feel the engine straining, and then suddenly you're going nowhere. The wheels are spinning, you start sliding backward, and your steering is useless." That's a terrifying spot to be in, especially with a heavy load.

The physics are simple but critical to understand:

- On a 2WD Forklift (Front-Wheel Drive): Going uphill moves weight away from the wheels that are doing the work. The more you load it and the steeper the hill, the less grip your drive wheels have. It's a recipe for failure.

- On a 4WD Forklift: Power is sent to all four wheels. As weight shifts to the rear, the back wheels dig in and continue to provide the push you need to climb safely and steadily. The machine works with the physics of the slope, not against it.

A crucial rule follows from this: always keep the load pointing up the incline. This means driving forward when going up, and reversing when going down, to keep the machine's center of gravity4 stable.

Why is going downhill so dangerous?

You assume that since gravity is on your side, going downhill is the easy part. But you've seen operators pick up too much speed, leading to panic braking and unstable loads.

Going downhill is dangerous because the forklift's momentum can easily overwhelm its brakes. Relying solely on brakes can cause them to overheat and fail, and sudden braking can shift the load, leading to a tip-over.

A client who manages a nursery built on a hillside told me his scariest moments were always going down, not up. He said, "The machine just wants to run away from you." This is especially true for standard warehouse forklifts, whose braking systems are designed for flat surfaces, not for managing the massive force of a loaded machine on an incline.

A safe descent isn't about braking harder; it's about controlling your speed from the start. That’s where a proper rough terrain forklift5 makes all the difference. Its transmission and engine are designed to help. By keeping the machine in a low gear, you engage "engine braking6." The engine itself holds the forklift at a slow, steady pace. You use the brakes only for coming to a complete stop, not for fighting gravity all the way down. This gives the operator total control.

Can you turn on a slope?

Your operator needs to reposition the forklift on a ramp or a sloped section of the site. It seems like a simple maneuver, but everything in you is screaming that it's a terrible idea.

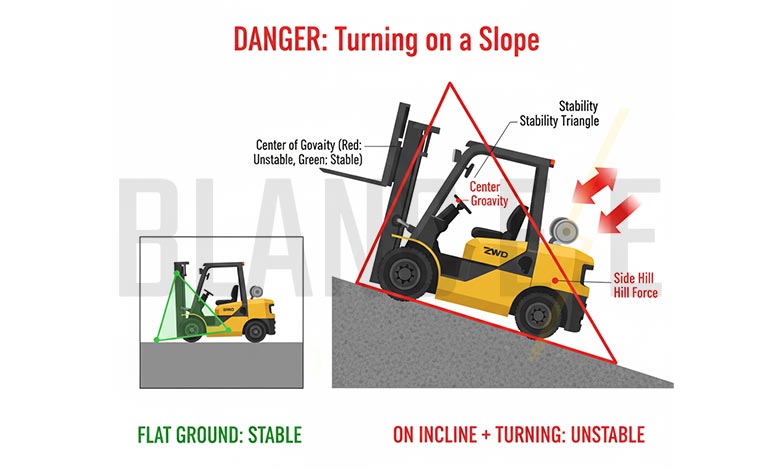

No, you must never turn on a slope. Turning shifts the machine’s center of gravity toward the downhill side. This drastically increases the risk of a sideways rollover7, one of the most dangerous types of forklift accidents8.

This is one of those non-negotiable rules. I always tell my customers to treat it like law. A forklift is designed to be stable on flat ground. The moment you put it on an incline, that side-to-side stability is dramatically reduced.

Think of it like this:

| Action | Proper Procedure | Why it's Critical |

|---|---|---|

| Needing to Turn | Drive fully down or up the slope to a flat area. Turn the machine around safely there, then drive straight on the new path. | It keeps the forklift's center of gravity safely within the wheelbase. Turning sideways moves the center of gravity outside the wheels, causing it to tip. |

| Navigating a Site | Plan your route to eliminate any need for maneuvers on inclines. Treat sloped areas as "straight line only" zones. | Proactive planning prevents operators from being put in a situation where they feel forced to make a dangerous turn. |

Any experienced operator knows this instinctively. They can feel the machine get "light" on the uphill side when they even think about turning. It's the machine telling you it's about to hit its tipping point. Always listen to that feeling.

Conclusion

Working on slopes is all about control and stability. Always travel straight, keep the load uphill, and most importantly, use a machine like a 4WD rough terrain forklift5 that's actually built for the job.

Explore how a 4WD machine enhances safety and traction on inclines, ensuring better control and stability. ↩

Learn why a 2WD forklift may not be suitable for sloped surfaces and the risks involved. ↩

Understand the mechanics behind traction loss and how to prevent it for safer operations. ↩

Learn about the importance of center of gravity in maintaining forklift stability and preventing accidents. ↩

Discover the unique features of rough terrain forklifts that enhance safety and performance on inclines. ↩

Discover how engine braking can help maintain control and prevent accidents during descents. ↩

Find out why sideways rollovers are dangerous and how to avoid them while operating on inclines. ↩

Understand the types of accidents that can occur on slopes and strategies to mitigate risks. ↩