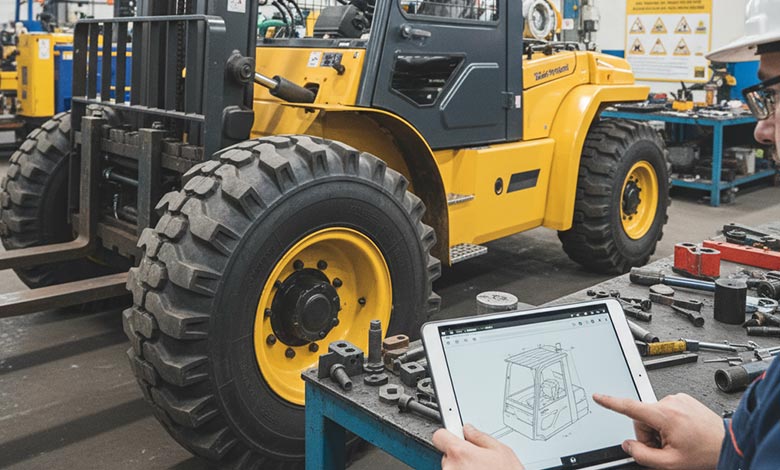

Buying a rough terrain forklift1 seems simple, but a mismatch between the machine and your job can cause major issues. To ensure safety and efficiency, you must start with a clear plan.

First, assess your worksite's terrain and the specific loads you'll handle. Then, choose a supplier with strong after-sales support and a proven reputation to guarantee your forklift's performance, safety, and long-term value.

As a supplier with over 15 years in this industry, I have helped hundreds of clients source the right equipment. The most successful projects always begin with a detailed needs assessment before even looking at models. This ensures the machine you get is a perfect fit for your work. Let's walk through the exact steps to make a confident and smart purchase.

How Do You Match a Forklift to Your Exact Job Site?

You see a powerful forklift online, but will it handle your steep, muddy site? A machine that gets stuck or can't safely lift your materials is a useless investment that hurts productivity.

You must analyze your terrain—including soil type and slopes—and define the weight and dimensions of your typical loads. This ensures the model you choose has the right off-road capability2 and rated capacity3 for safe, stable operation.

In my years of exporting, I've seen that experience is not just about how long a company has been in business, but about its specific experience with your type of equipment. Rough terrain forklifts are specialized machines. They operate in harsh conditions and require a deep understanding of structural stress, powertrain dynamics, and durability.

When you evaluate a supplier, ask about their core focus. Have they been making this type of equipment for years, or is it a new addition to their catalog? A specialized manufacturer will have a wealth of knowledge to share. For instance, at BLANC-ELE, our focus on this machinery has allowed us to serve diverse industries from agriculture to mining across the globe. This background helps us anticipate challenges and build machines that last. Look for a partner whose history aligns with your needs. A good supplier will be proud to share their track record and connect you with feedback from other customers.

Why is After-Sales Support So Critical for Rough Terrain Forklifts?

The forklift has been delivered, but a critical part fails. Now you are facing costly downtime because you can't get a replacement or technical help, turning your project schedule upside down.

Because these forklifts work in harsh conditions, you need a supplier who guarantees timely repair support, a reliable supply of spare parts, and technical training. Strong after-sales service4 is essential to ensure equipment durability and uptime.

After-sales support is my personal measure of a supplier's commitment. A transaction ends at the sale; a partnership continues for the life of the machine. Rough terrain equipment takes a beating. It’s not a question of if it will need maintenance, but when. The speed and quality of the support you receive at that moment defines your total cost of ownership.

Before you buy, ask detailed questions:

- Spare Parts Logistics: How do you guarantee the availability of common wear parts? What is the process for ordering and shipping them to my country?

- Technical Support: If my local mechanic has a problem, is there an experienced engineer I can talk to? Do you provide service manuals and troubleshooting guides in English?

- Training: Do you offer training for our operators or maintenance staff?

We built our reputation on providing this level of support because we know that a forklift that isn't working is costing our partner money.

Can You Get a Forklift Customized For Special Conditions?

Your work site has unique challenges, like a need for extra operator protection or a very specific lifting task. A standard machine just won't be safe or efficient enough for the job.

Yes, if you have special requirements, you must communicate them to the supplier. A capable manufacturer can offer custom configurations5 like special tires, reinforced suspensions, or added protective guards to match the forklift to your exact work environment.

Customization is where a true engineering partner shines. Many of my clients have needs that go beyond the standard catalog. For example, a customer working in a dusty quarry needed extra air filtration and a sealed cabin to protect both the operator and the engine. Another client in forestry required special grapple attachments and reinforced chassis guards.

Don't be afraid to ask for modifications. A good supplier will welcome this conversation. It's a chance for them to demonstrate their technical expertise. Common customizations include:

- Specialized Tires: Foam-filled to prevent punctures or with specific tread patterns for mud.

- Strengthened Components: Reinforced masts or suspension for handling extreme loads.

- Safety Add-ons: Extra work lights, blue spot safety lamps, or custom protective cages.

Your forklift should be a tool perfectly shaped for your hand. Discussing customization ensures you get exactly that.

How Do You Calculate the True Cost of a Forklift?

One supplier's price is much lower, which looks tempting. But this low initial price can hide high long-term expenses that end up costing your company much more over the machine's life.

Look beyond the purchase price and calculate the Total Cost of Ownership (TCO)6. This includes fuel consumption, scheduled maintenance costs7, and potential repair expenses. A high-quality, efficient machine often has a lower TCO.

As a procurement manager, you are an expert at managing budgets. I always encourage my clients to think like an asset manager. The real cost of a machine isn't what you pay today; it's what you pay over the next five to ten years. A cheaper machine that consumes more fuel or breaks down frequently will quickly become the most expensive piece of equipment you own.

When evaluating quotes, ask the supplier for data on:

| Cost Factor | What to Ask | Why It's Important |

|---|---|---|

| Fuel/Energy Use | What is the average fuel consumption per hour? | Fuel is a major ongoing operational expense. |

| Maintenance | What are the recommended service intervals? | Frequent or expensive service adds up. |

| Component Life | What is the expected life of key parts? | Quality components reduce breakdown frequency. |

By comparing these factors, you can make a decision based on value, not just price. A well-built machine from a reputable supplier will deliver a better return on your investment.

What Are the Key Steps for Compliance and Shipping?

You've found the perfect forklift, but what's next? You need to ensure it meets your country's standards and that it arrives on time without damaging your project schedule or incurring surprise fees.

Confirm the forklift meets your country's safety and environmental standards8, like CCC in China. Also, clarify the production lead time9, shipping arrangements10, and insurance coverage with your supplier to ensure a smooth delivery process.

The final phase of procurement is just as important as the first. A great machine is no good to you if it's stuck in customs or arrives late. A professional supplier will guide you through this process.

Compliance and Safety

First, ensure the machine is certified. In China, CCC (China Compulsory Certification) is a key mark of quality and safety. Also, confirm the machine adheres to standards for emissions and noise levels relevant to your region. Operator safety is also paramount—ensure training protocols are in place.

Logistics and Delivery

Next, get firm dates for the production and shipping schedule. Ask your supplier:

- What is the production lead time9?

- How will the machine be packed and protected for sea transport?

- What does the shipping insurance cover?

Clear communication on these points will prevent delays and ensure your equipment arrives safely and on schedule, ready to get to work.

Conclusion

By assessing your needs, verifying your supplier, and planning for the long term, you can confidently source a high-quality rough terrain forklift1 from China that will power your projects forward.

Explore this link to discover top-rated rough terrain forklifts that suit various job sites and conditions. ↩

This resource will explain the key features that enhance a forklift's performance on rough terrains. ↩

Find out how to accurately assess a forklift's rated capacity to ensure safety and efficiency. ↩

Discover the critical role of after-sales service in maintaining the longevity and efficiency of heavy machinery. ↩

Find out how custom configurations can optimize forklifts for specific job site challenges. ↩

Understanding TCO helps you make better financial decisions when purchasing heavy equipment. ↩

Get insights into maintenance costs to better budget for your forklift's long-term care. ↩

Explore the key safety and environmental standards that forklifts must comply with for safe operation. ↩

Understanding production lead times is crucial for planning your equipment procurement effectively. ↩

This guide will help you navigate the complexities of shipping heavy machinery efficiently. ↩